Driving Towards Sustainability: The Rise of Natural Fiber Composites in Automotive Innovation

Driving Towards Sustainability: The Rise of Natural Fiber Composites in Automotive Innovation

Natural fiber composites are revolutionizing industries by providing a sustainable alternative to traditional materials, offering both durability and eco-friendliness.

When we think about cars, we often focus on speed, comfort, and fuel efficiency. But today, there’s something bigger happening in the world of automotive innovation—something that could shape how we drive in the future. And it’s all about natural fiber composites. But why should you care about this? How does this impact the cars we drive and the world we live in? In a nutshell, natural fiber composites are driving the future of the automotive industry toward greater sustainability. And that’s something we can all get behind.

What Are Natural Fiber Composites and Why Should They Matter to You?

We get it—composites might sound like a technical term, and most of us aren’t engineers. But here’s the deal: natural fiber composites are materials made from natural fibers like hemp, flax, or jute, mixed with resins to create a strong, lightweight, and durable material. They’re becoming more and more popular in automotive manufacturing because they’re not only effective, but they’re also much more eco-friendly than traditional materials like fiberglass or carbon fiber.

So, why should we care? Well, it’s simple: these materials are lighter, they help reduce fuel consumption, and, most importantly, they’re much better for the planet. This shift toward natural fibers in the automotive industry is part of a larger movement of driving the future with sustainability in mind. It’s all about reducing carbon footprints, cutting down on waste, and creating greener, more sustainable options in every aspect of our daily lives.

How Natural Fiber Composites Are Changing Automotive Innovation

You’ve probably noticed the buzz around electric cars, renewable energy, and sustainable practices in almost every industry. But did you know that natural fiber composites are playing a huge role in driving this change within the automotive world? Here’s how they’re doing it.

1. Reducing Weight and Improving Efficiency

One of the key benefits of natural fiber composites is their lightweight nature. Traditional car parts, like the dashboard, door panels, and even the car’s interior components, can be made with these materials. Less weight means less energy needed to move the car, which in turn reduces fuel consumption. For electric vehicles (EVs), every gram counts in improving battery range. The shift towards these sustainable materials makes a noticeable difference in efficiency.

2. Sustainability at Its Core

Sustainability is more than just a buzzword; it’s becoming a necessity in the fight against climate change. Natural fibers are renewable resources, meaning they’re grown from the earth, not mined or processed in harmful ways. By using these fibers in car manufacturing, we’re reducing reliance on petroleum-based materials, cutting down on harmful emissions, and encouraging a green economy. This is a win-win for both the environment and the automotive industry.

3. Durability and Versatility

Another great thing about natural fiber composites is their strength. These materials are strong enough to withstand the wear and tear of daily use, meaning they’re durable and reliable. They can also be molded into various shapes and sizes, making them perfect for all types of automotive applications. Whether it’s the interior of your car or the body panels, these materials can do it all.

4. Reducing Carbon Footprint

By replacing traditional synthetic materials with natural fiber composites, automotive companies are significantly reducing their carbon footprint. These fibers require far less energy to produce, and they absorb carbon dioxide from the air while they grow. The shift towards these materials is a crucial part of climate action, allowing the automotive industry to reduce its environmental impact.

Real-Life Examples of Natural Fiber Composites in Cars

You’re probably wondering, “Do any real-world cars actually use natural fiber composites?” The answer is yes, and more than you might think. Here are a couple of examples that highlight how these materials are already being used in the industry:

BMW i3: The BMW i3 is a prime example of how natural fiber composites can be used in automotive innovation. The car’s interior is made with renewable materials, including natural fiber-reinforced plastics. These sustainable materials help reduce the car’s environmental impact while maintaining durability and style.

Ford’s Sustainable Car Interiors: Ford has been using natural fiber composites for years to create sustainable car interiors. Their approach includes using materials like soy-based foam for seats, and hemp fibers for sound insulation, reducing the need for petroleum-based products.

Mercedes-Benz: Mercedes-Benz has also made strides in using natural fibers, particularly in their interior panels. These fibers help keep the weight down while still meeting the high standards of performance, safety, and comfort that consumers expect.

The Role of Natural Fiber Composites in Driving the Future

So, what’s next for the automotive industry? The future of sustainable automotive manufacturing lies in natural fiber composites and other biomaterials. By integrating these materials into everyday car production, automakers are making strides in reducing their reliance on traditional, non-renewable resources. It’s not just about fuel efficiency anymore—it’s about creating products that contribute to a circular economy, where materials are reused, recycled, and repurposed.

This shift also paves the way for upcycling opportunities, where waste materials from other industries can be used to create high-quality automotive parts. By embracing these practices, we can help reduce resource consumption and minimize waste, all while driving toward a more sustainable future.

The Bigger Picture: Sustainability Beyond the Car

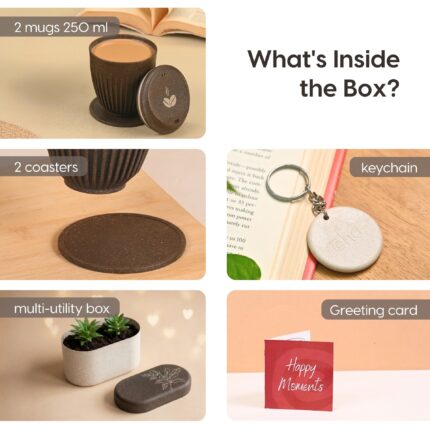

It’s clear that natural fiber composites are not only changing the automotive industry but are also pushing the envelope on how sustainability can be integrated into other sectors. Whether we’re talking about sustainable tableware, eco-friendly office products, or even gifting options like bamboo planters and reusable cups, the trend toward using renewable resources is spreading. These materials are popping up everywhere in lifestyle products, and that’s exciting for both consumers and the planet.

The more we embrace the use of biomaterials, the closer we get to reducing carbon emissions, preventing crop-burning, and minimizing our overall environmental impact. From the cars we drive to the products we use at home and in the office, sustainability is taking the front seat—and that’s a change worth celebrating.

Conclusion: Steering Toward a Greener Future

As the automotive industry continues to evolve, natural fiber composites are at the forefront of driving innovation. Not only do these materials help reduce emissions, improve fuel efficiency, and create sustainable car parts, but they also offer a blueprint for how we can build a greener, cleaner future. The move toward sustainable automotive innovation is just one piece of the puzzle, and as we embrace sustainability in every aspect of our lives—from products at home to the vehicles we drive—we’re making significant strides toward a healthier planet.

Let’s keep driving the future in the right direction, one sustainable choice at a time.

Visit eha’s range of sustainable products to choose, made with biocomposite materials using crop-waste such as rice husk, bamboo fibers and coffee husk.

If you are looking at developing new range of earth friendly products speak to experts at Mynusco.